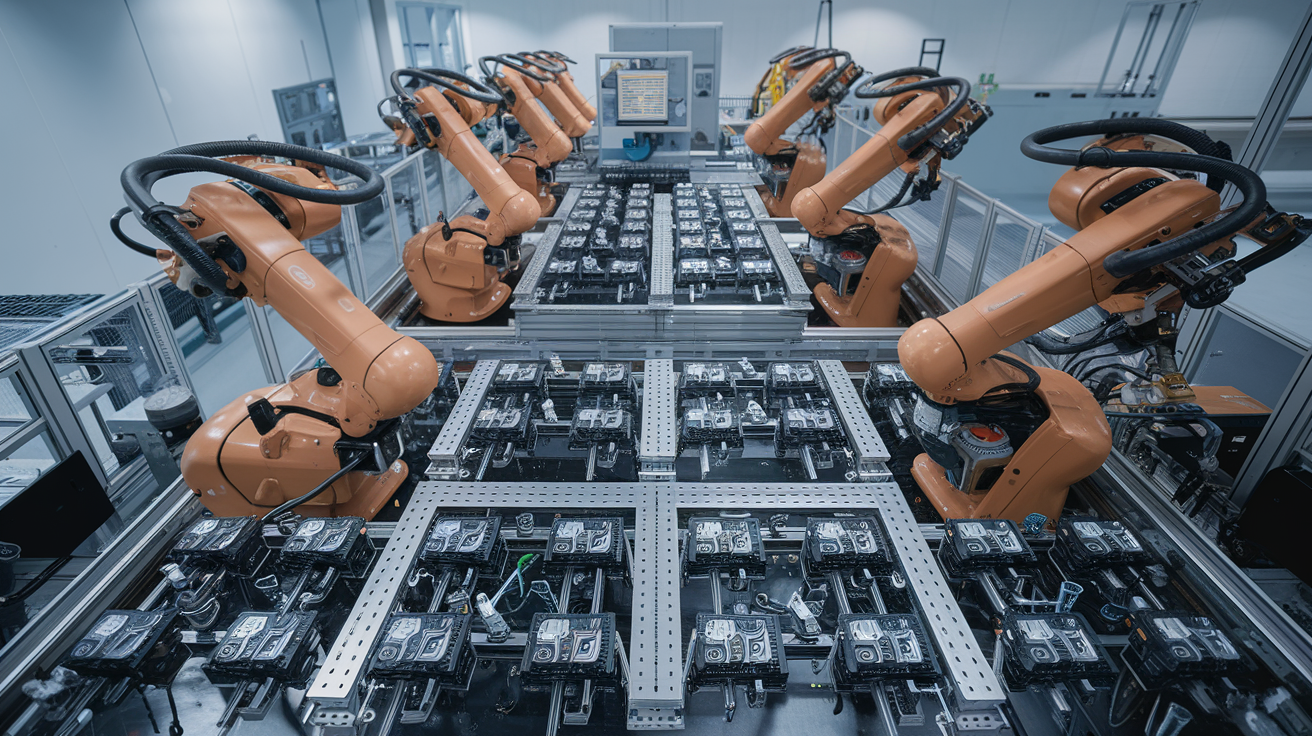

The Future of Adhesive Dispensing – How Robotics is Revolutionizing Manufacturing

Introduction

In today’s competitive manufacturing landscape, automation is the key to efficiency and quality. Robotic glue dispensing systems are transforming industries by enhancing precision, reducing waste, and increasing speed. From electronics to aerospace, manufacturers are replacing manual adhesive application with next-generation robotic solutions.

1. The Evolution of Glue Dispensing

Traditional glue application was a manual, time-consuming process that often resulted in inconsistent bonding, waste, and errors. The introduction of robotic dispensers revolutionized the industry, providing:

✅ High-precision adhesive placement

✅ Reduced material consumption

✅ Automated, repeatable processes

2. Industries Benefiting from Robotic Dispensing

🔹 Electronics & PCB Manufacturing: Achieves micro-dispensing accuracy for delicate components.

🔹 Automotive & Aerospace: Ensures strong, lightweight bonding for high-performance parts.

🔹 Medical Devices: Meets sterile, cleanroom-certified adhesive application standards.

➡ Looking for an advanced solution? Explore our Y-Series Robotic Dispensers for precision adhesive automation.

3. Why Automation is the Future

Manufacturers worldwide are shifting towards smart factories where robotics, AI, and IoT drive higher efficiency. According to Automation World, Industry 4.0 innovations will increase factory automation adoption by 50% by 2028.

Conclusion

Investing in robotic adhesive dispensing improves quality, reduces costs, and future-proofs manufacturing. At Adhesiomatic, we provide industry-leading automated dispensing solutions tailored to your needs.

📞 Contact us today to automate your adhesive application process!

Add a comment