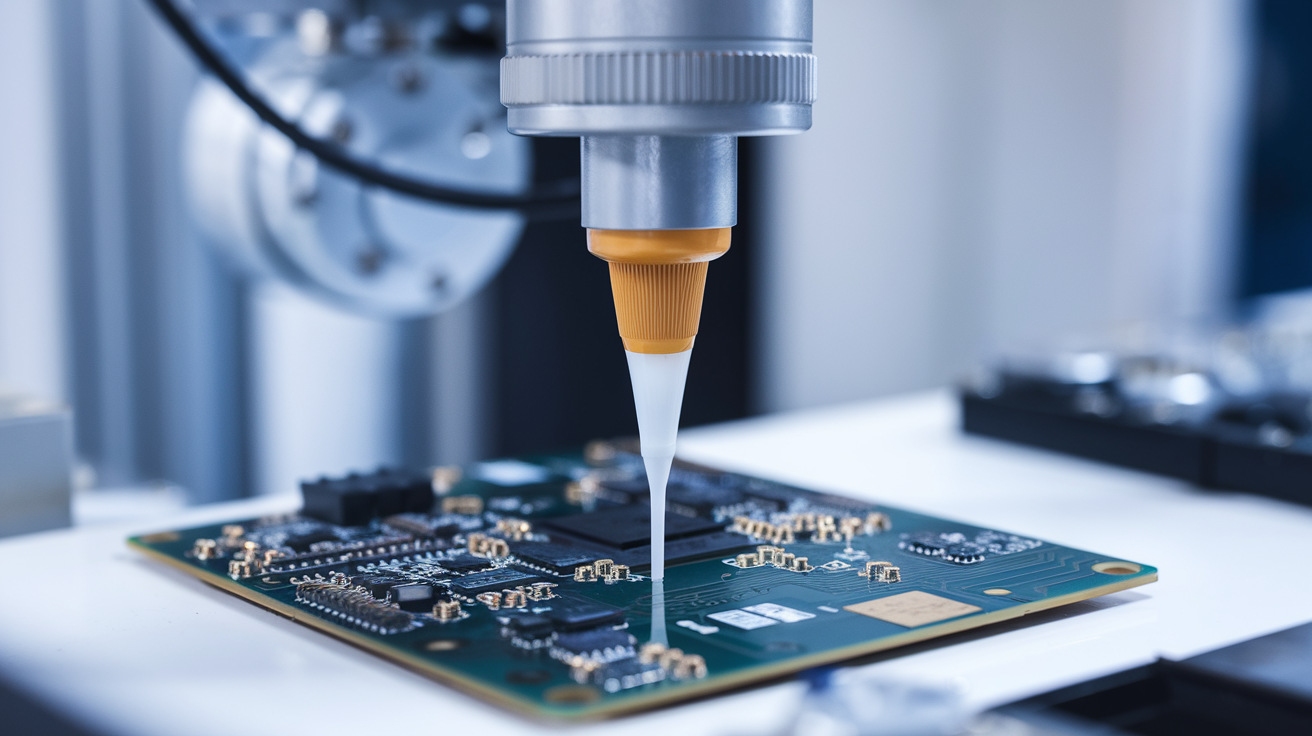

5 Common Glue Dispensing Mistakes & How to Avoid Them

Introduction

Investing in a robotic glue dispenser can significantly improve production quality and efficiency. However, choosing the right system depends on several factors, including application type, adhesive properties, and automation level. Let’s explore how to find the perfect dispenser for your needs.

1. Understand Your Industry Needs

Each industry has unique adhesive application challenges:

- Electronics: Requires high-precision micro-dispensing.

- Automotive & Aerospace: Needs strong, heat-resistant adhesives.

- Medical Devices: Demands cleanroom-certified, sterile solutions.

➡ Need help selecting the right system? Check out our Product Catalog to find the perfect match.

2. Choose the Right Dispensing Technology

Different adhesives require specialized dispensing methods:

✔ UV Adhesives & Epoxy: Require controlled flow systems.

✔ Silicone & Conformal Coatings: Work best with multi-axis robotics.

✔ Solder Paste & Heat Dissipation Paste: Need precision, low-waste dispensing.

3. Integration & Automation Capabilities

A good robotic dispenser should seamlessly integrate into your existing production line. Look for:

✅ Multi-axis movement for complex applications

✅ AI-powered vision systems for accuracy

✅ Automated needle calibration for consistency

According to Manufacturing Global, companies that invest in smart automation solutions see a 30% increase in production efficiency.

Conclusion

Selecting the right robotic dispenser ensures efficiency, precision, and cost savings. At Adhesiomatic, we offer tailored automation solutions designed to enhance your manufacturing process.

📞 Get in touch today to find the best dispenser for your business

Add a comment